-

你好,欢迎来到东莞市樟木头宇涛塑胶原料经营部官网!

|

| 品牌 | 美国基础创新塑料 |

| 货号 | 9066 |

| 用途 | 水管/管道/饮用水 |

| 牌号 | 9066 |

| 型号 | 9066 |

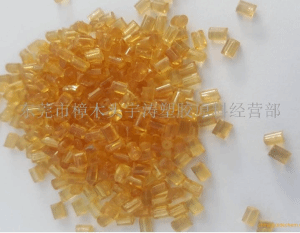

| 品名 | PEI |

| 外形尺寸 | 颗粒 |

| 厂家 | 基础创新塑料 |

| 是否进口 | 是 |

高流动 ULTEM PEI 9066

PEI 9066 高流动性聚醚酰亚胺混合物。符合FAR 25.853和OSU 65/65标准,具有低毒性、烟雾和火焰演变。符合环保要求

High flow Polyetherimide blend. Meets FAR 25.853 and OSU 65/65 with low toxicity, smoke, and flame evolution. ECO Conforming.

| TYPICAL PROPERTIES (1) | |||

|

MECHANICAL机械性能

|

Value | Unit | Standard |

|

Tensile Stress, yld, Type I, 5 mm/min / 抗张程度,屈服,类型I,5 mm/min

|

96

|

MPa

|

ASTM D 638

|

|

Tensile Stress, brk, Type I, 5 mm/min / 抗张程度,断裂,类型I,5 mm/min

|

88

|

MPa

|

ASTM D 638

|

|

Tensile Strain, brk, Type I, 5 mm/min / 拉伸伸长,断裂,类型I,5 mm/min

|

65

|

%

|

ASTM D 638

|

|

Tensile Modulus, 5 mm/min / 拉伸模量,5 mm/min

|

3240

|

MPa

|

ASTM D 638

|

|

Flexural Stress, yld, 2.6 mm/min, 100 mm span

|

144

|

MPa

|

ASTM D 790

|

|

Flexural Modulus, 2.6 mm/min, 100 mm span

|

3170

|

MPa

|

ASTM D 790

|

|

IMPACT

|

Value | Unit | Standard |

|

Izod Impact, notched, 23°C / 悬臂梁缺口冲击强度23°C

|

85

|

J/m

|

ASTM D 256

|

|

Izod Impact, Reverse Notched, 3.2 mm

|

1975

|

J/m

|

ASTM D 256

|

|

Instrumented IMPACT Energy @ peak / 仪表控制抗冲击能量 @ 峰值, 23°C

|

67

|

J

|

ASTM D 3763

|

|

Instrumented IMPACT Energy @ peak / 仪表控制抗冲击能量 @ 峰值, -30

|

58

|

J

|

ASTM D 3763

|

|

THERMAL

|

Value | Unit | Standard |

|

HDT, 1.82 MPa, 6.4 mm, unannealed / 热变形温度,1.82 MPa, 6.4 mm, 未退火

|

195

|

°C

|

ASTM D 648

|

|

PHYSICAL

|

Value | Unit | Standard |

|

Specific Gravity/比重

|

1.28

|

–

|

ASTM D 792

|

|

Mold Shrinkage, flow, 3.2 mm / 模塑收缩量,流动,3.2 mm

|

0.5 – 0.7

|

%

|

SABIC Method

|

|

Mold Shrinkage, xflow, 3.2 mm / 模塑收缩量,横向,3.2 mm

|

0.5 – 0.7

|

%

|

SABIC Method

|

|

Melt Flow Rate / 熔流率, 337°C/6.6 kgf

|

11

|

g/10 min

|

ASTM D 1238

|

|

FLAME CHARACTERISTICS

|

Value | Unit | Standard |

|

OSU total heat release (2 minute test)

|

10

|

kW-min/m2

|

FAR 25.853

|

|

OSU peak heat release rate (5 minute test)

|

50

|

kW/m2

|

FAR 25.853

|

|

Source GMD, last updated:01/13/2000

|

|

Processing

|

| Parameter | ||

|

Injection Molding

|

Value | Unit |

|

Drying Temperature / 干燥温度

|

135

|

°C

|

|

Drying Time / 干燥时间

|

4 – 6

|

hrs

|

|

Drying Time (Cumulative) / 干燥时间(累积的)

|

24

|

hrs

|

|

Maximum Moisture Content / 含湿量

|

0.02

|

%

|

|

Melt Temperature / 熔体温度

|

340 – 360

|

°C

|

|

Nozzle Temperature / 注嘴温度

|

330 – 355

|

°C

|

|

Front – Zone 3 Temperature / 前区3温度

|

340 – 360

|

°C

|

|

Middle – Zone 2 Temperature / 中区2温度

|

325 – 350

|

°C

|

|

Rear – Zone 1 Temperature / 后区1温度

|

315 – 340

|

°C

|

|

Mold Temperature / 模具温度

|

135 – 165

|

°C

|

|

Back Pressure / 背压

|

0.3 – 0.7

|

MPa

|

|

Screw Speed / 螺杆速度

|

40 – 70

|

rpm

|

|

Shot to Cylinder Size / 每次注射量占料筒熔胶总量的百分比

|

40 – 60

|

%

|

|

Vent Depth / 排气孔深度

|

0.025 – 0.076

|

mm

|